Block Nuts

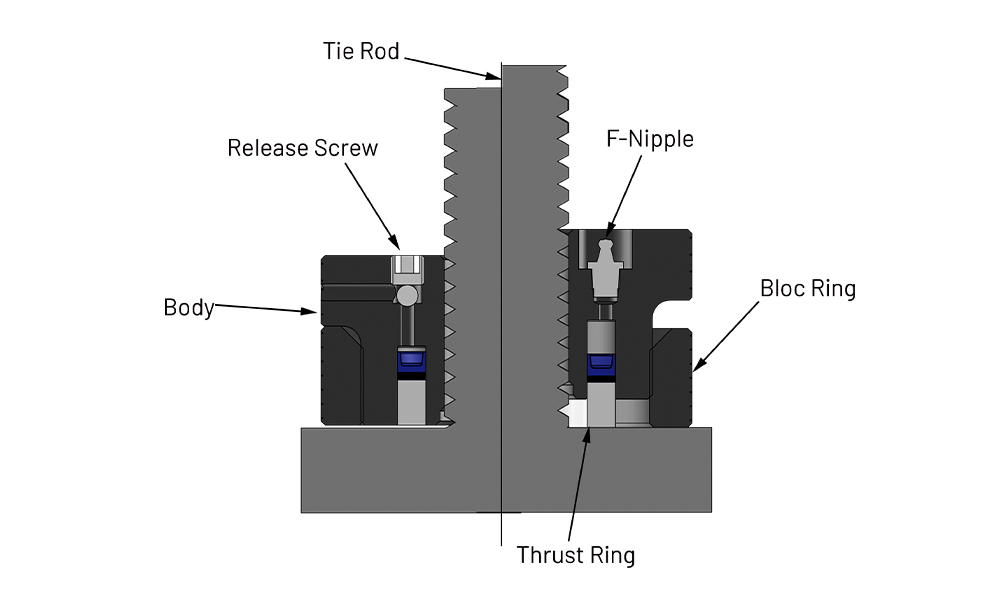

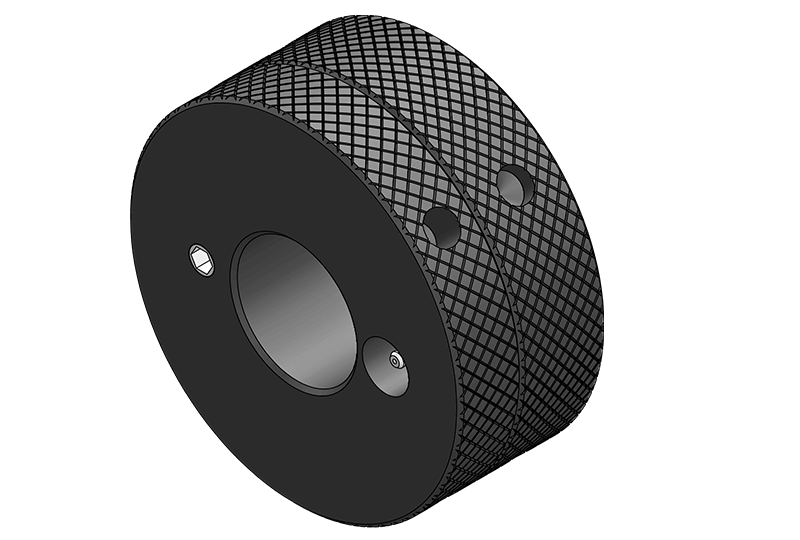

Greas-Bloc Nut Series F-410 with MECHANICAL “BLOC-RING”

Amtec Greas-Bloc Nuts are the fastest way to tension tie rods, while avoiding thread damage altogether.

Simply spin the Greas-Bloc Nut onto the tie rod until it bottoms on the counter face and then pressurize the nut using your Amtec pump.

Once tension force is reached, tighten the bloc ring against the counter face and then release the pressure from the nut using the release screw. Your clamping force will remain until you once again pressurize the Greas-Bloc nut and back out the bloc ring. After once again depressurizing the nut, it easily spins off the tie rod.

Fact: Up to 80% of clamping force can be lost to friction in tightening mechanical nuts and bolts. “Super Nuts” require tightening of “Jack Screws,” which are subject to the same frictional lost, in addiction to corrosion and distortion.

Selection:

- Specify bolt size and thread details

- Specify available flat counter face diameter around bolt

- Specify minimum clamping force required

- Confirm end face access to grease nipple is convenient

- Advise quantity required

- Custom designs to suit applications

Industries

Downloads

Features

- Amtec “Greas-Bloc” Nuts use grease pressure to apply axial clamping force without any loss of force through friction. Clamping force from 123 KN (27,650 lbs) and higher depending on size of nut required.

- Available stainless steel nut bodies resist corrosion during installation lifetime.

- Mechanical “Bloc-Ring” maintains initial clamping force throughout in-service term, regardless of time.