H-Type Nuts

Series H-3.4 & H-3.10 with AXIALLY LOCATED FLUID PORTS

Actuated by manual oil pump or hydraulic power unit. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

Industries

Downloads

Features

- Standard black oxide finish for 120°C max.(250°F)

- Special finishes for service up to 240°C max.(460°F)

- Alloy tool steel body parts

- Stainless steel, electroless nickel or chromium plating for optional corrosion resistance

- BSPP or SAE O-ring boss ports

- All components rated at 840 bar max. (12,180 psi)

- Aluminum nuts are half the weight as steel

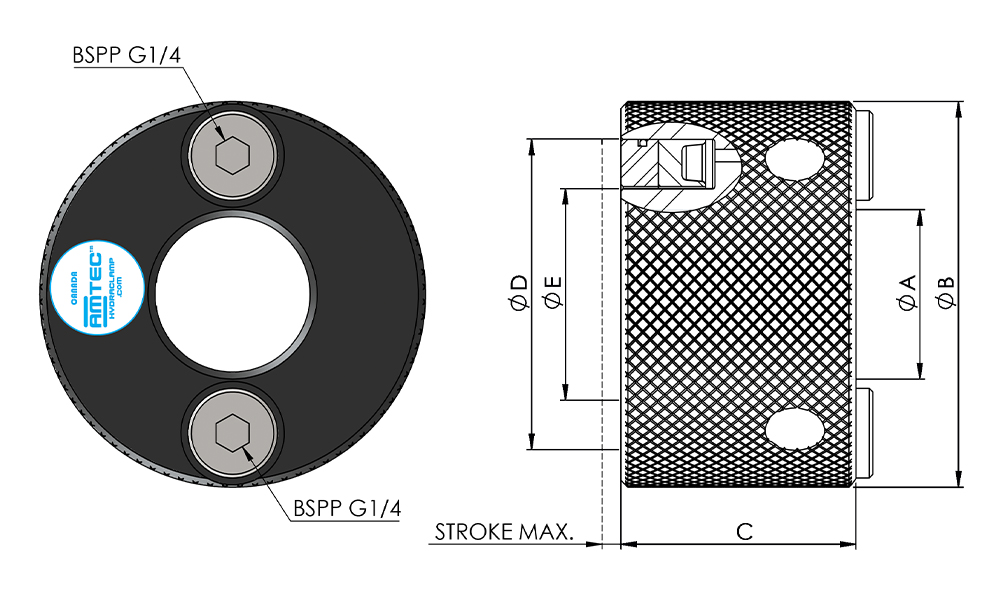

| Max Arbor Thread Size | Cannot Exceed Minimum Tool ø | Verify diameters D&E contact an uninterrupted suface | Select Stroke as Required | Ensure Adquate Force Has Been Selected | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Max Thread ø | Nut Diameter | Thrust Ring Size | Thrust Ring Stroke | Nut Width | Clamping Force | Weight | |||||||||||

| A | B | D - OD | E - ID | S | C | 400 BAR | 700 BAR | |||||||||||

| mm | Inch | mm | Inch | mm | Inch | mm | Inch | mm | Inch | mm | Inch | kN | Tons | kN | Tons | KG | Pounds | |

| H-3.405 | 36 | 1.750 | 82 | 3.228 | 66 | 2.598 | 46 | 1.811 | 4 | 0.157 | 50 | 1.969 | 70 | 8 | 123 | 13 | 3.0 | 6.6 |

| H-3.1005 | 36 | 1.750 | 85 | 3.346 | 66 | 2.598 | 46 | 1.811 | 10 | 0.394 | 60 | 2.362 | 70 | 8 | 123 | 13 | 3.0 | 6.6 |

| H-3.407 | 52 | 2.000 | 98 | 3.858 | 82 | 3.228 | 62 | 2.441 | 4 | 0.157 | 50 | 1.969 | 90 | 10 | 158 | 18 | 3.0 | 6.6 |

| H-3.1007 | 52 | 2.000 | 102 | 4.016 | 82 | 3.228 | 62 | 2.441 | 10 | 0.394 | 60 | 2.362 | 90 | 10 | 158 | 18 | 3.0 | 6.6 |

| H-3.408 | 68 | 2.625 | 116 | 4.567 | 100 | 3.937 | 80 | 3.150 | 4 | 0.157 | 50 | 1.969 | 113 | 13 | 198 | 22 | 3.0 | 6.6 |

| H-3.1008 | 68 | 2.625 | 120 | 4.724 | 100 | 3.937 | 80 | 3.150 | 10 | 0.394 | 60 | 2.362 | 113 | 13 | 198 | 22 | 3.4 | 7.5 |

| H-3.409 | 82 | 3.250 | 131 | 5.157 | 115 | 4.528 | 95 | 3.740 | 4 | 0.157 | 50 | 1.969 | 131 | 14 | 230 | 26 | 3.4 | 7.5 |

| H-3.1009 | 82 | 3.250 | 135 | 5.315 | 115 | 4.528 | 95 | 3.740 | 10 | 0.394 | 60 | 2.362 | 131 | 14 | 230 | 26 | 4.0 | 8.8 |

| H-3.410 | 100 | 3.875 | 148 | 5.827 | 130 | 5.118 | 112 | 4.409 | 4 | 0.157 | 50 | 1.969 | 137 | 15 | 239 | 27 | 4.5 | 9.9 |

| H-3.1010 | 100 | 3.875 | 152 | 5.984 | 130 | 5.118 | 112 | 4.409 | 10 | 0.394 | 60 | 2.362 | 137 | 15 | 239 | 27 | 5.8 | 12.8 |

| H-3.1011 | 125 | 4.875 | 185 | 7.283 | 160 | 6.299 | 138 | 5.433 | 10 | 0.394 | 60 | 2.362 | 205 | 23 | 360 | 40 | 6.8 | 15.0 |

| H-3.1012 | 142 | 5.625 | 200 | 7.874 | 175 | 6.890 | 155 | 6.102 | 10 | 0.394 | 60 | 2.362 | 207 | 23 | 363 | 41 | 7.3 | 16.1 |

| H-3.10125 | 156 | 6.125 | 215 | 8.465 | 190 | 7.480 | 170 | 6.693 | 10 | 0.394 | 60 | 2.362 | 226 | 25 | 396 | 45 | 8.5 | 18.7 |

| H-3.1013 | 165 | 6.500 | 228 | 8.976 | 200 | 7.874 | 180 | 7.087 | 10 | 0.394 | 60 | 2.362 | 238 | 27 | 417 | 47 | 11.0 | 24.2 |

| H-3.1014 | 186 | 7.375 | 250 | 9.843 | 222 | 8.740 | 202 | 7.953 | 10 | 0.394 | 60 | 2.362 | 266 | 30 | 466 | 52 | 12.0 | 26.4 |

| H-3.1015 | 198 | 7.750 | 268 | 10.551 | 240 | 9.449 | 215 | 8.465 | 10 | 0.394 | 60 | 2.362 | 357 | 40 | 625 | 70 | 13.5 | 29.7 |

| H-3.1015.5 | 218 | 8.500 | 288 | 11.339 | 260 | 10.236 | 235 | 9.252 | 10 | 0.394 | 60 | 2.362 | 389 | 43 | 680 | 76 | 14.0 | 30.8 |

| H-3.1016.1 | 226 | 8.875 | 298 | 11.732 | 270 | 10.630 | 245 | 9.646 | 10 | 0.394 | 60 | 2.362 | 404 | 45 | 707 | 78 | 11.5 | 25.3 |

| H-3.1017.0 | 242 | 9.500 | 313 | 12.323 | 285 | 11.220 | 260 | 10.236 | 10 | 0.394 | 60 | 2.362 | 428 | 48 | 749 | 84 | 14.0 | 30.8 |

| H-3.1018.0 | 260 | 10.250 | 344 | 13.543 | 310 | 12.205 | 280 | 11.024 | 10 | 0.394 | 65 | 2.559 | 556 | 62 | 973 | 109 | 16.5 | 36.3 |

| H-3.1019.0 | 280 | 11.000 | 364 | 14.331 | 330 | 12.992 | 300 | 11.811 | 10 | 0.394 | 65 | 2.559 | 594 | 67 | 1039 | 116 | 25.0 | 55.0 |

| H-3.1019.5 | 305 | 12.000 | 392 | 15.433 | 355 | 13.976 | 325 | 12.795 | 10 | 0.394 | 70 | 2.756 | 640 | 71 | 1121 | 125 | 24.8 | 54.6 |

| H-3.1020.0 | 308 | 12.125 | 406 | 15.984 | 366 | 14.409 | 330 | 12.992 | 10 | 0.394 | 70 | 2.756 | 787 | 88 | 1377 | 154 | 35.0 | 77.0 |

| H-3.1021.0 | 336 | 13.250 | 448 | 17.638 | 400 | 15.748 | 360 | 14.173 | 10 | 0.157 | 70 | 2.756 | 955 | 107 | 1671 | 187 | 39.0 | 85.8 |

| H-3.1022.0 | 366 | 13.250 | 460 | 18.110 | 422 | 16.614 | 390 | 15.354 | 10 | 0.394 | 70 | 2.756 | 816 | 91 | 1428 | 160 | 37.0 | 81.4 |

| H-3.1023.0 | 396 | 15.625 | 486 | 19.134 | 450 | 17.717 | 420 | 16.535 | 10 | 0.157 | 70 | 2.756 | 820 | 92 | 1435 | 161 | 32.5 | 71.5 |