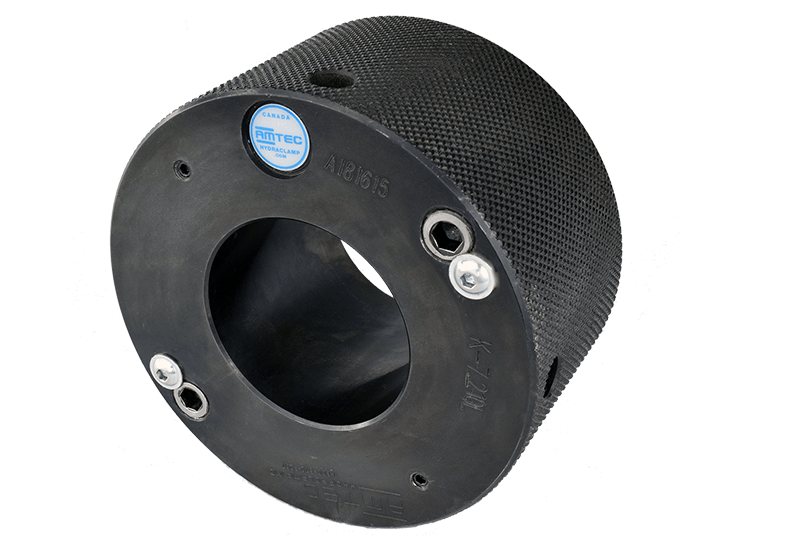

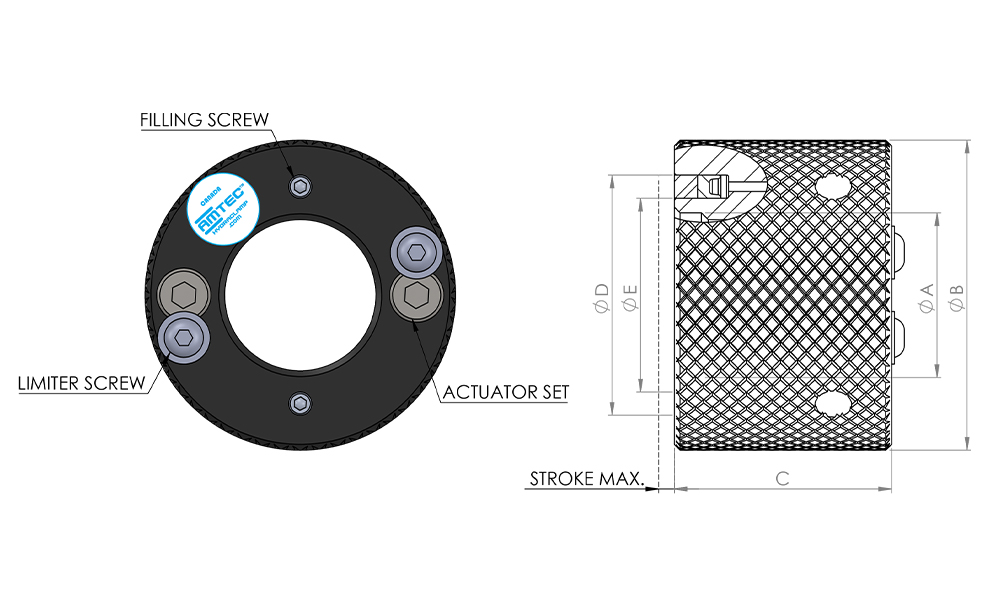

K-Type Nuts

Series K-7.1, K-7.2 & K-7.4 with AXIAL ACTUATOR SCREW & PISTON

A sealed grease system without pressure release to atmosphere. Actuated by a hand held hex wrench. Axial pistons provide a compact OD. Thrust Ring offers 1 to 4 mm of axial travel.

Industries

Downloads

Features

- Standard black oxide finish for 120°C max. (250°F)

- Alloy tool steel body parts

- Stainless steel, electroless nickel or chromium

- Plating for optional corrosion resistance

- Self-aligning annular thrust ring

- Clean, efficient, hand-operated clamping system

| Max Arbor Thread Size | Cannot Exceed Minimum Tool ø | Verify diameters D&E contact an uninterrupted suface | Select Stroke as Required | Ensure Adquate Force Has Been Selected | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Max Thread ø | Nut Diameter | Thrust Ring Size | Thrust Ring Stroke | Nut Width | Clamping Force | Weight | |||||||||||

| A | B | D - OD | E - ID | S | C | 10Nm - 89in-lb | 20Nm - 178in-lb | |||||||||||

| mm | Inch | mm | Inch | mm | Inch | mm | Inch | mm | Inch | mm | Inch | kN | Tons | kN | Tons | KG | Pounds | |

| K-7.101L | 16 | 0.625 | 44 | 1.732 | 28 | 1.102 | 22 | 0.866 | 1 | 0.039 | 42 | 1.654 | 12 | 1.2 | 24 | 2.4 | 0.4 | 0.9 |

| K-7.201L | 16 | 0.625 | 44 | 1.732 | 28 | 1.102 | 22 | 0.866 | 2 | 0.079 | 42 | 1.654 | 12 | 1.2 | 24 | 2.4 | 0.4 | 0.9 |

| K-7.102L | 20 | 0.750 | 48 | 1.890 | 34 | 1.338 | 26 | 1.023 | 1 | 0.039 | 48 | 1.890 | 19 | 2 | 38 | 4 | 0.5 | 1.1 |

| K-7.202L | 20 | 0.750 | 48 | 1.890 | 34 | 1.338 | 26 | 1.023 | 2 | 0.079 | 48 | 1.890 | 19 | 2 | 38 | 4 | 0.5 | 1.1 |

| K-7.103L | 24 | 0.875 | 56 | 2.205 | 40 | 1.574 | 32 | 1.260 | 1 | 0.039 | 48 | 1.890 | 23 | 2.3 | 45 | 4.5 | 0.7 | 1.5 |

| K-7.203L | 24 | 0.875 | 56 | 2.205 | 40 | 1.574 | 32 | 1.260 | 2 | 0.079 | 48 | 1.890 | 23 | 2.3 | 45 | 4.5 | 0.7 | 1.5 |

| K-7.104L | 30 | 1.125 | 64 | 2.520 | 46 | 1.811 | 38 | 1.496 | 1 | 0.039 | 48 | 1.890 | 30 | 3 | 60 | 6 | 0.9 | 2.0 |

| K-7.204L | 30 | 1.125 | 64 | 2.520 | 46 | 1.811 | 38 | 1.496 | 2 | 0.079 | 48 | 1.890 | 30 | 3 | 60 | 6 | 0.9 | 2.0 |

| K-7.105L | 36 | 1.375 | 70 | 2.756 | 52 | 2.047 | 44 | 1.732 | 1 | 0.039 | 48 | 1.890 | 30 | 3 | 60 | 6 | 1.0 | 2.2 |

| K-7.205L | 36 | 1.375 | 70 | 2.756 | 52 | 2.047 | 44 | 1.732 | 2 | 0.079 | 48 | 1.890 | 30 | 3 | 60 | 6 | 1.0 | 2.2 |

| K-7.106L | 42 | 1.625 | 80 | 3.150 | 62 | 2.441 | 50 | 1.969 | 1 | 0.039 | 56 | 2.205 | 48 | 5 | 95 | 9.5 | 1.5 | 3.3 |

| K-7.206L | 42 | 1.625 | 80 | 3.150 | 62 | 2.441 | 50 | 1.969 | 2 | 0.079 | 56 | 2.205 | 48 | 5 | 95 | 9.5 | 1.6 | 3.5 |

| K-7.107L | 52 | 2.000 | 90 | 3.543 | 72 | 2.835 | 60 | 2.362 | 1 | 0.039 | 62 | 2.441 | 56 | 6 | 112 | 11 | 1.9 | 4.2 |

| K-7.207L | 52 | 2.000 | 90 | 3.543 | 72 | 2.835 | 60 | 2.362 | 2 | 0.079 | 62 | 2.441 | 56 | 6 | 112 | 11 | 2.0 | 4.4 |

| K-7.108L | 68 | 2.625 | 110 | 4.331 | 92 | 3.622 | 82 | 3.228 | 1 | 0.039 | 62 | 2.441 | 62 | 6 | 123 | 12 | 2.4 | 5.3 |

| K-7.208L | 68 | 2.625 | 110 | 4.331 | 92 | 3.622 | 82 | 3.228 | 2 | 0.079 | 62 | 2.441 | 62 | 6 | 123 | 12 | 2.5 | 5.5 |

| K-7.109L | 80 | 3.125 | 120 | 4.724 | 100 | 3.937 | 88 | 3.465 | 1 | 0.039 | 70 | 2.756 | 80 | 8 | 160 | 16 | 3.2 | 7.0 |

| K-7.209L | 80 | 3.125 | 120 | 4.724 | 100 | 3.937 | 88 | 3.465 | 2 | 0.079 | 70 | 2.756 | 80 | 8 | 160 | 16 | 3.3 | 7.3 |

| K-7.210L | 100 | 3.875 | 148 | 5.827 | 125 | 4.921 | 110 | 4.331 | 2 | 0.079 | 80 | 3.150 | 83 | 9 | 166 | 17 | 7.2 | 15.8 |

| K-7.410L | 100 | 3.875 | 160 | 6.299 | 125 | 4.921 | 110 | 4.331 | 4 | 0.157 | 98 | 3.858 | 55 | 6 | 110 | 11 | 10.0 | 22.0 |

*Actual thrust ring force will vary as much as 25% due to actuator thread friction. To obtain accurate setup pressure, please see Series 550 K-Nuts on page 82.