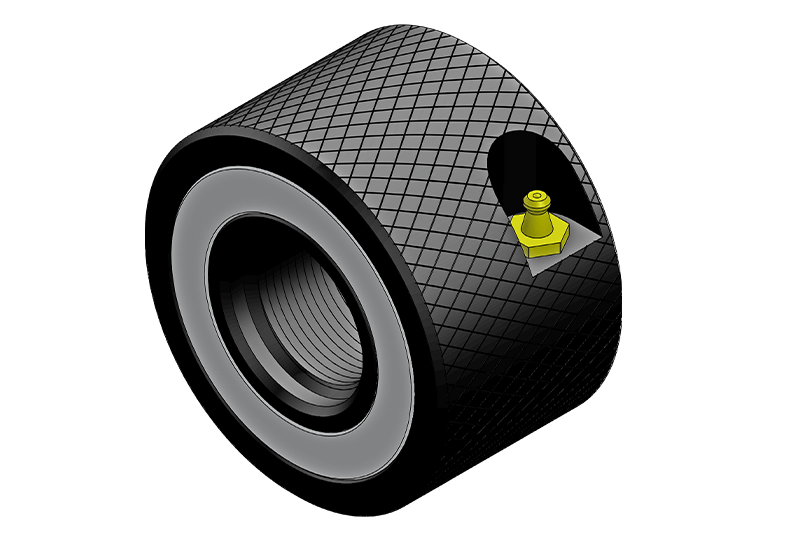

F-Type Nuts

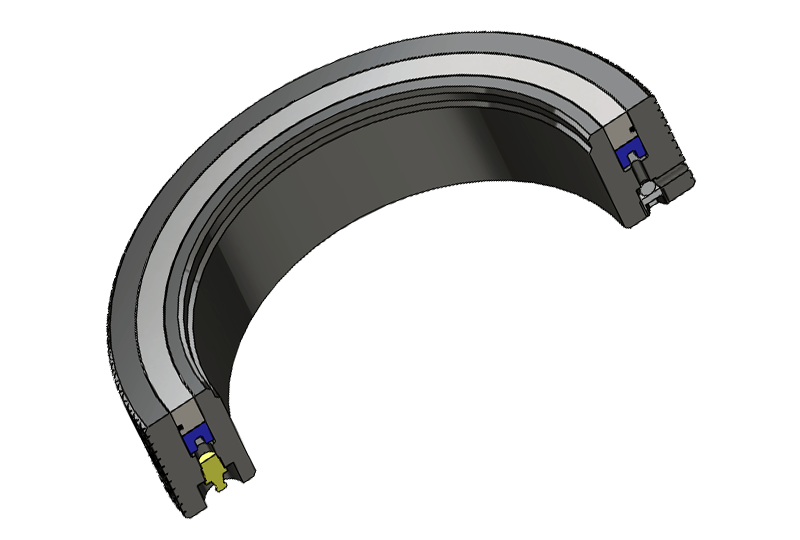

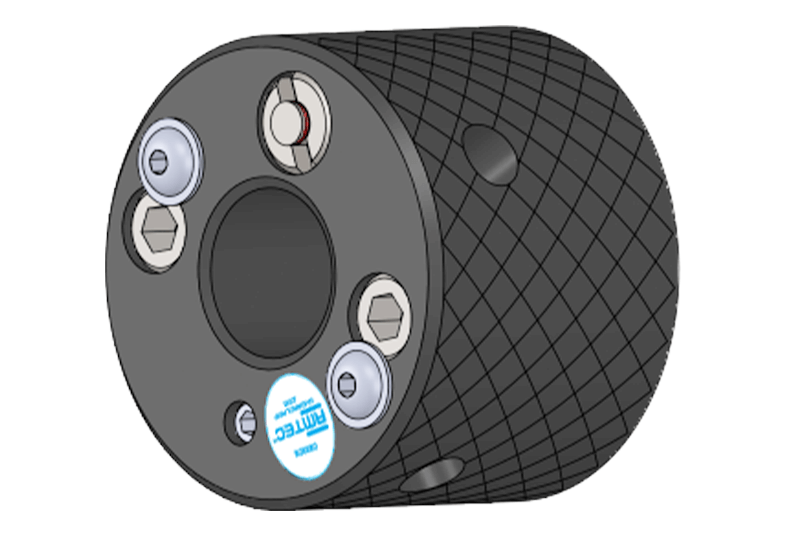

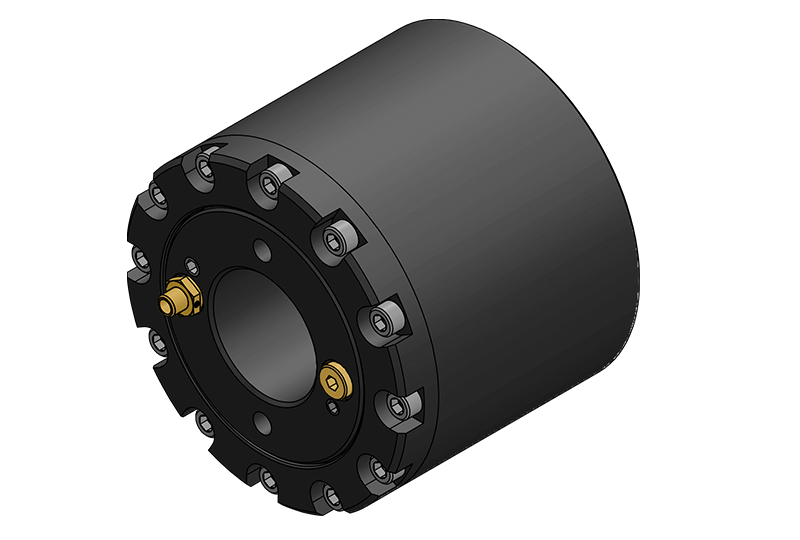

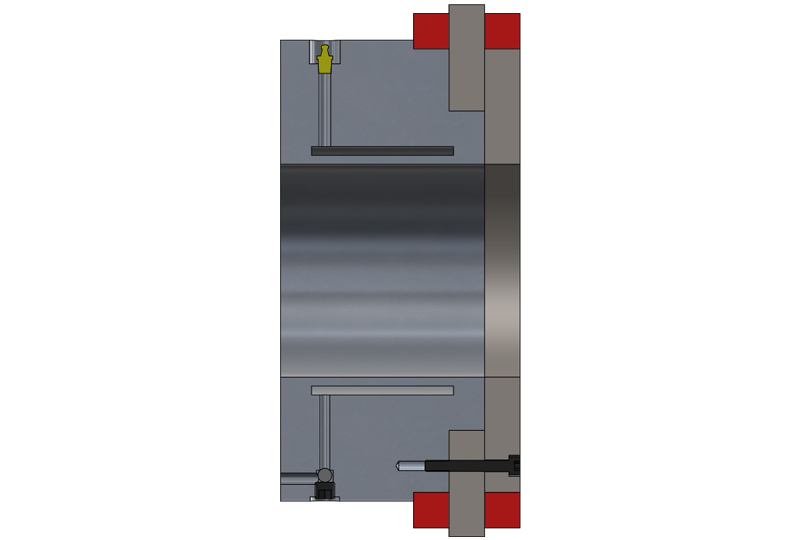

Series F-8.4 & F-8.10

with RADIALLY LOCATED F-NIPPLE and RELEASE SCREW

Actuated by manual or motorized grease pump. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

Learn moreF-Type Nuts

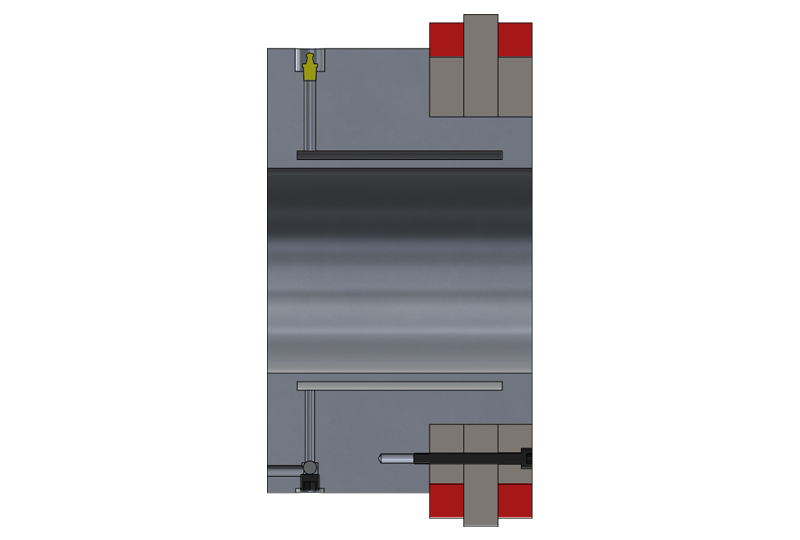

Max-Force Series F-8.4 & F-8.10

with RADIALLY LOCATED F-NIPPLE and RELEASE SCREW

Actuated by manual or motorized grease pump. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

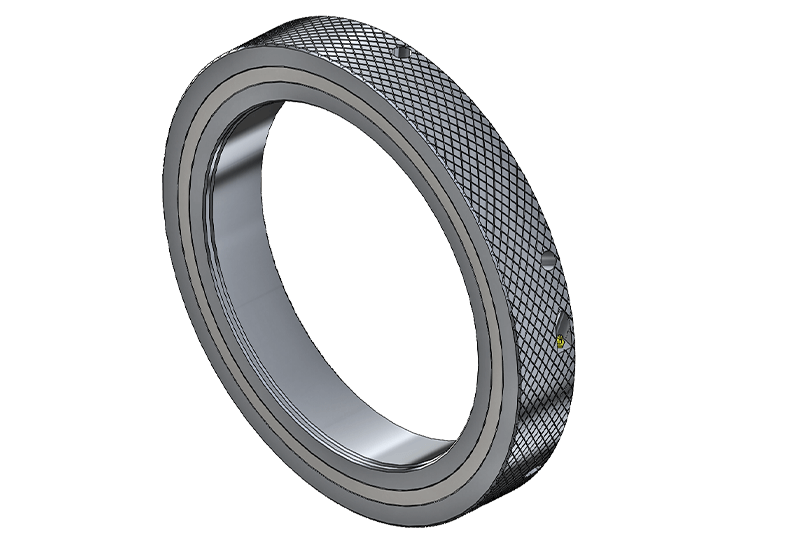

Learn moreF-Type Nuts

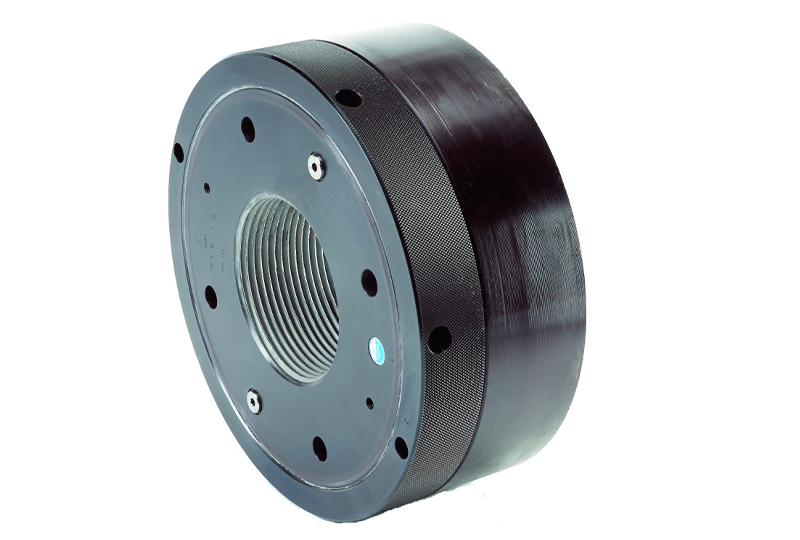

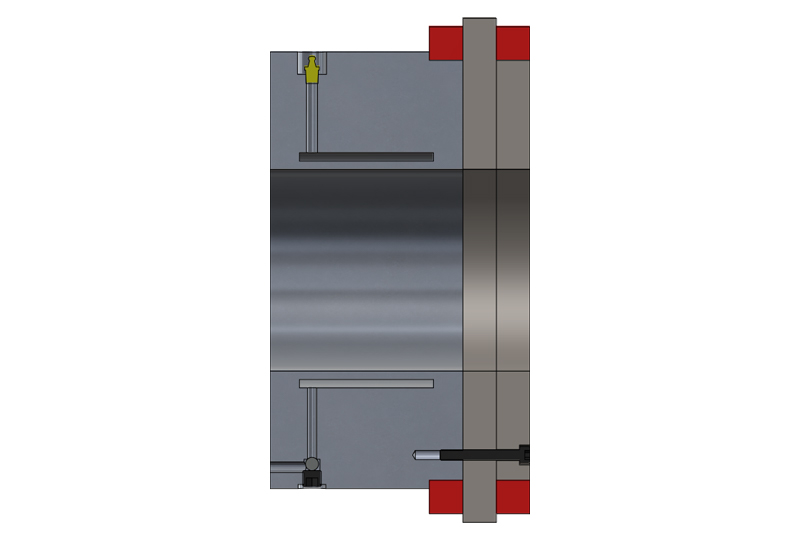

Aircraft Quality Aluminum Series F-8.4 & F-8.10

with RADIALLY LOCATED F-NIPPLE & RELEASE SCREW

Actuated by manual or motorized grease pump. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

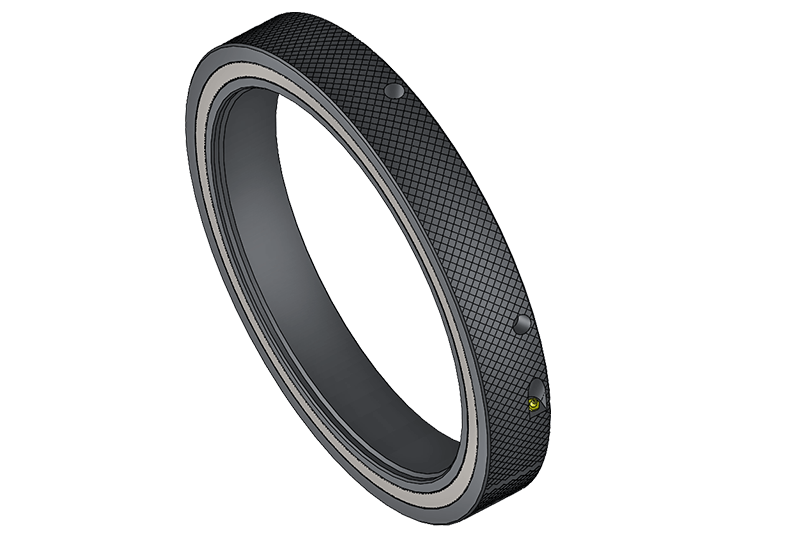

Learn moreF-Type Nuts

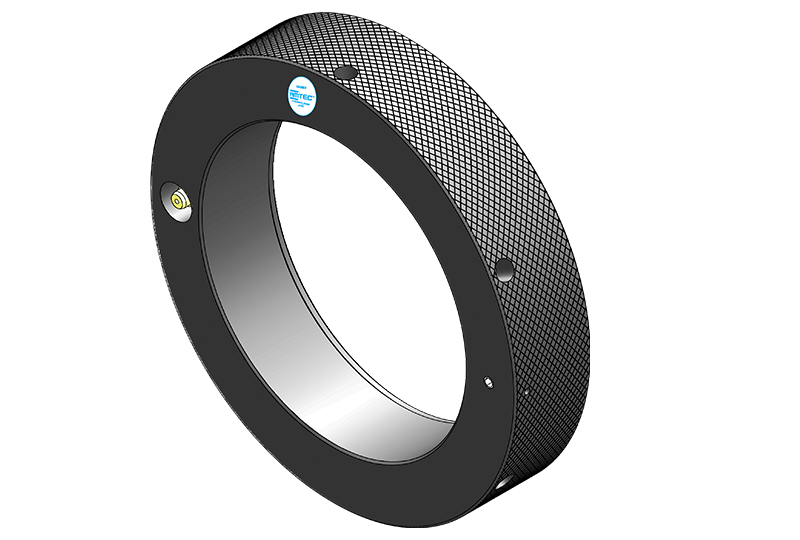

Series F-9.4 & F-9.10

with AXIAL F-NIPPLE & RELEASE SCREW

Actuated by manual or motorized grease pump. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

Learn moreF-Type Nuts

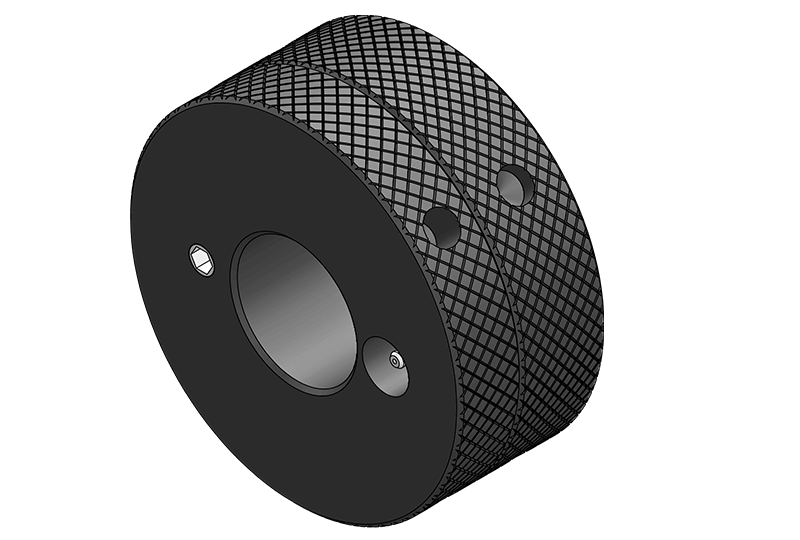

Max-Force Series F-9.4 & F-9.10

with AXIAL F-NIPPLE & RELEASE SCREW

Actuated by manual or motorized grease pump. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

Learn moreF-Type Nuts

Aircraft Quality Aluminum Series F-9.4 & F-9.10

with AXIAL F-NIPPLE & RELEASE SCREW

Actuated by manual or motorized grease pump. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

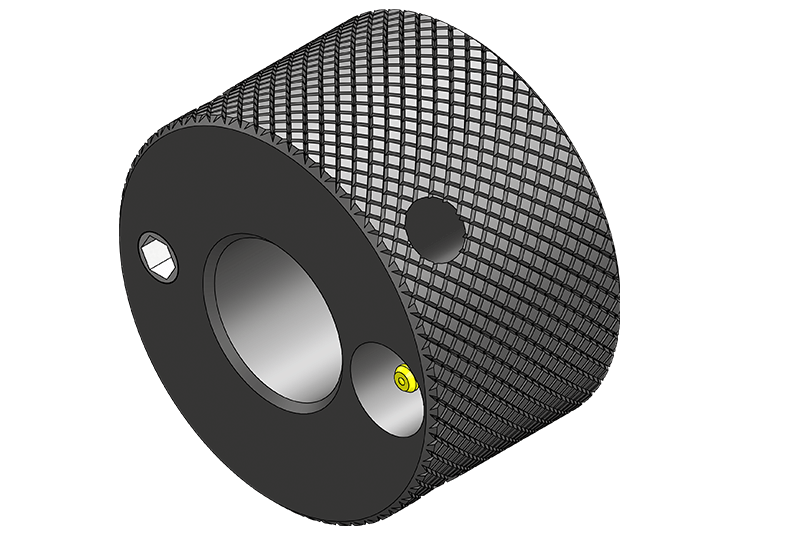

Learn moreK-Type Nuts

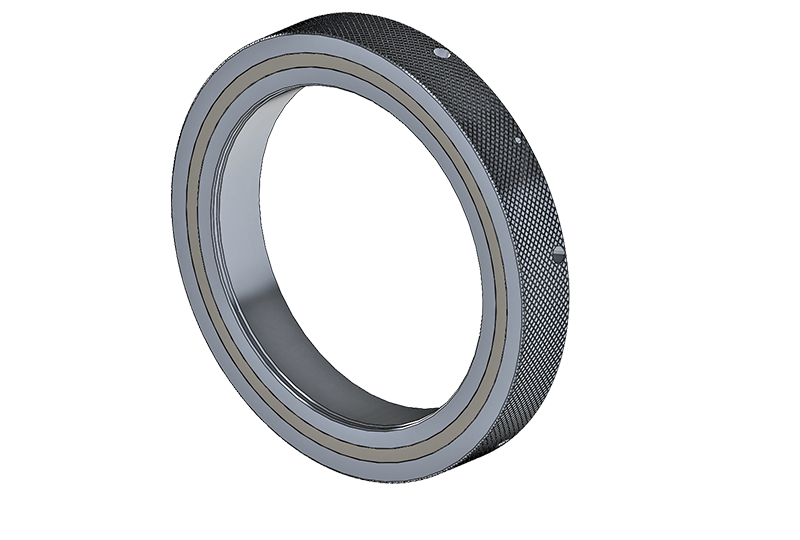

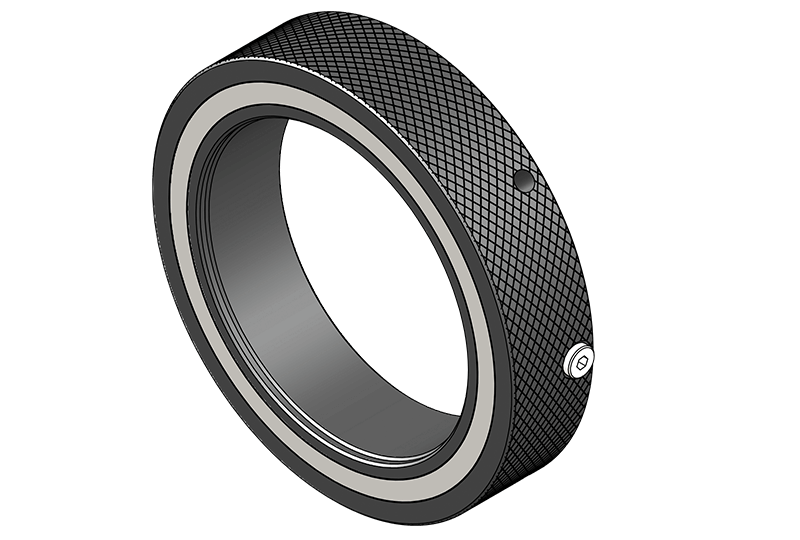

Series K-6.1 & K-6.2

with RADIALLY LOCATED ACTUATOR SCREW & PISTON

A sealed grease system without pressure release to atmosphere. Actuated by a hand held hex wrench. Transverse pistons provide a narrow profile. Thrust Ring offers 1 or 2 mm of axial travel.

Learn moreK-Type Nuts

Series K-7.1, K-7.2 & K-7.4

with AXIAL ACTUATOR SCREW & PISTON

A sealed grease system without pressure release to atmosphere. Actuated by a hand held hex wrench. Axial pistons provide a compact OD. Thrust Ring offers 1 to 4 mm of axial travel.

Learn moreK-Type Nuts

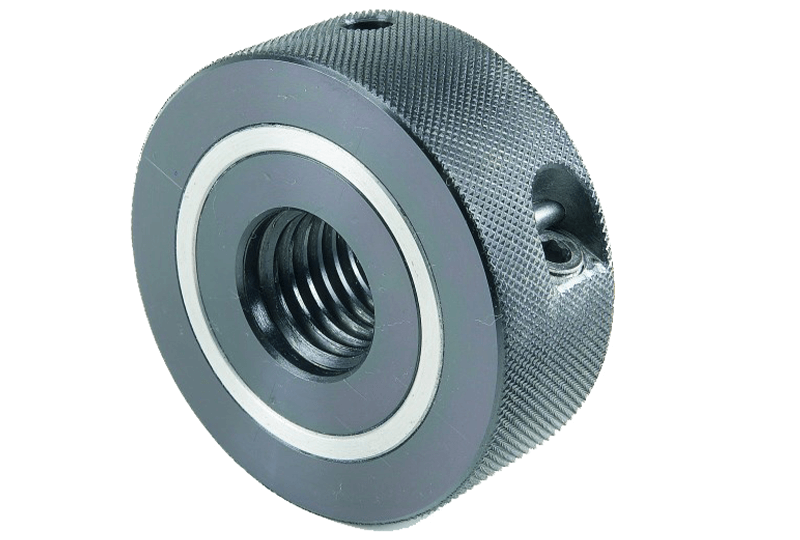

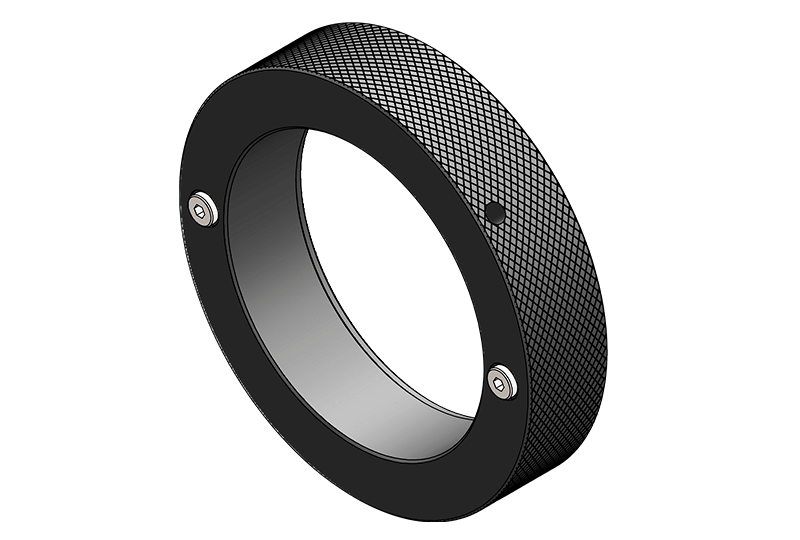

Series K-025.XXX.610

with AXIAL ACTUATOR SCREW & PISTON and INDICATOR PIN

A sealed grease system without pressure release to atmosphere. Actuated by a hand held hex wrench. Axial pistons provide a compact OD. Thrust Ring offers 1 to 4 mm of axial travel. Indicator Pin pops up when full nut force is achieved.

Learn moreK-Type Nuts

Series K-025.XXX.710

with AXIAL ACTUATOR SCREW & PISTON and INDICATOR PIN

A sealed grease system without pressure release to atmosphere. Actuated by a hand held hex wrench. Axial pistons provide a compact OD. Thrust Ring offers 1 to 4 mm of axial travel. Indicator Pin pops up when full nut force is achieved.

Learn moreGX-Type Nuts

Series GX-4.4 & GX-4.10

with RADIALLY LOCATED GX-NIPPLE

Actuated by hydraulic power unit or manual oil pump. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

Learn moreGX-Type Nuts

Series GX-5.4 & GX-5.10

with AXIALLY LOCATED GX-NIPPLE

Actuated by hydraulic power unit or manual oil pump. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

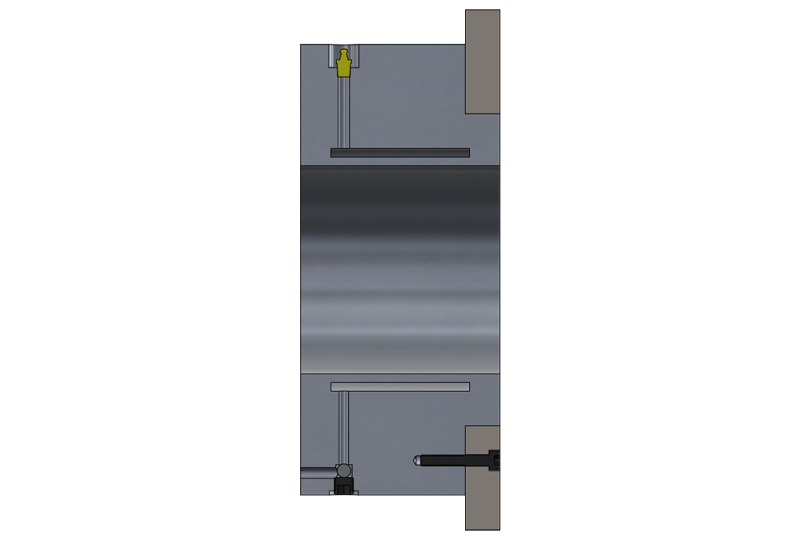

Learn moreH-Type Nuts

Series H-2.4 & H-2.10

with TRANSVERSE FLUID PORTS

Actuated by manual oil pump or hydraulic power unit. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

Learn moreH-Type Nuts

Series H-3.4 & H-3.10

with AXIALLY LOCATED FLUID PORTS

Actuated by manual oil pump or hydraulic power unit. Self-aligning annular thrust ring with 4 or 10 mm maximum axial travel.

Learn moreStep Nuts

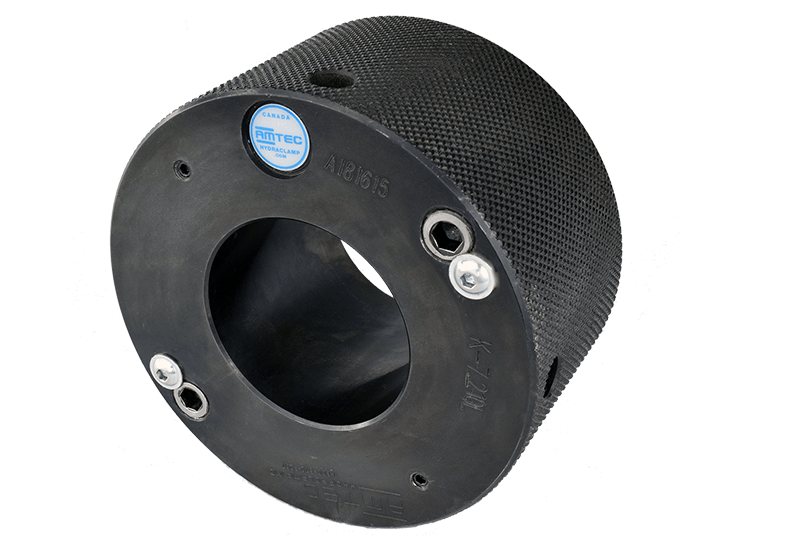

Series 024 – Single Acting

The Amtec Hydraclamp Step Nut provides accurately controlled pre-tensioning service for tie-rods, shafts and arbors in rolling mills, pinion stands, hearing equipment and presses.

Learn moreStep Nuts

Series 026 – Double Acting

The double acting Amtec Hydraclamp Step Nut provides a custom-designed pressure chamber to exceed any pre-tensioning requirement, as well as a low pressure retraction chamber for easy reset.

Learn moreBlock Nuts

Series 023

Hydraulic pre-tensioning with mechanical locking for long term clamping at precise tie rod elongation.

Learn moreBlock Nuts

Greas-Bloc Nut Series F-410

with MECHANICAL “BLOC-RING”

Actuated by manual or motorized pump for use with grease. Self-aligning thrust ring with 10mm maximum axial travel.

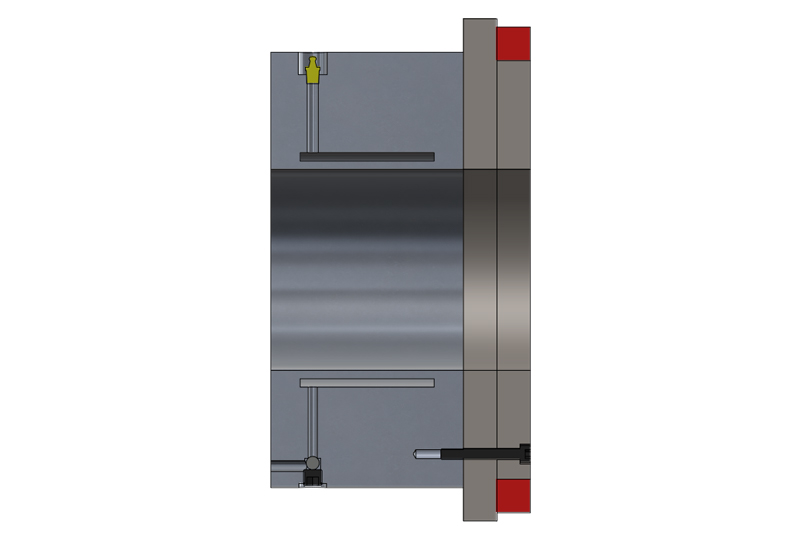

Learn moreClamp Rings

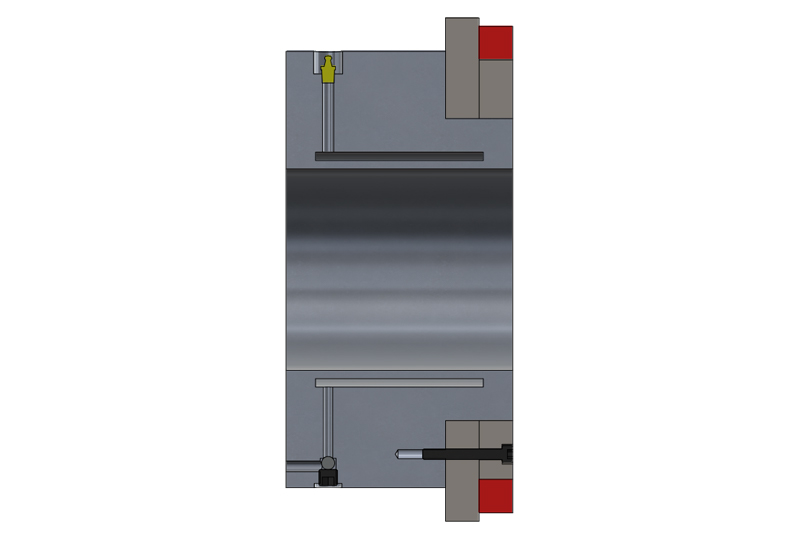

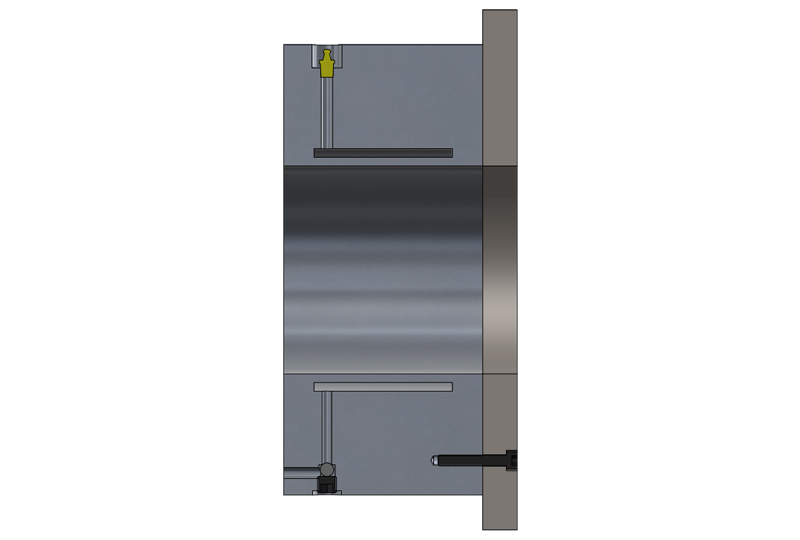

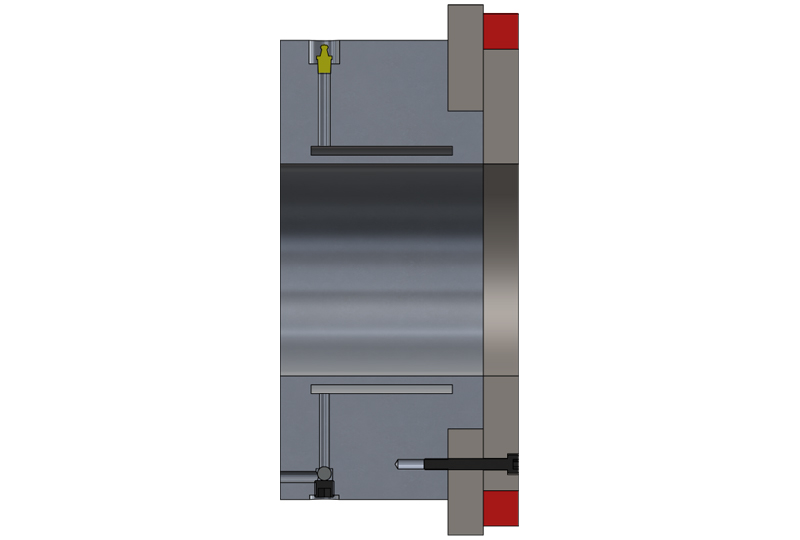

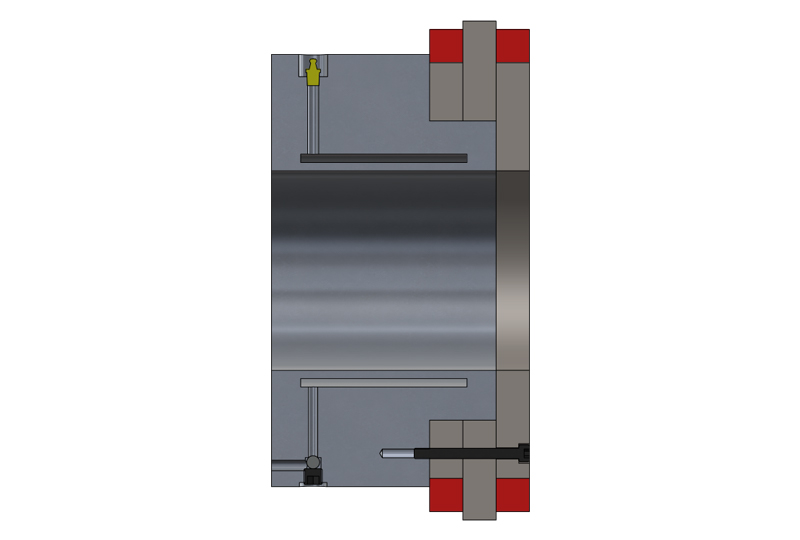

Model 901

Circular knife is mounted on the seat and bolted against the shoulder. The hydraulic chamber extends under the knife seat.

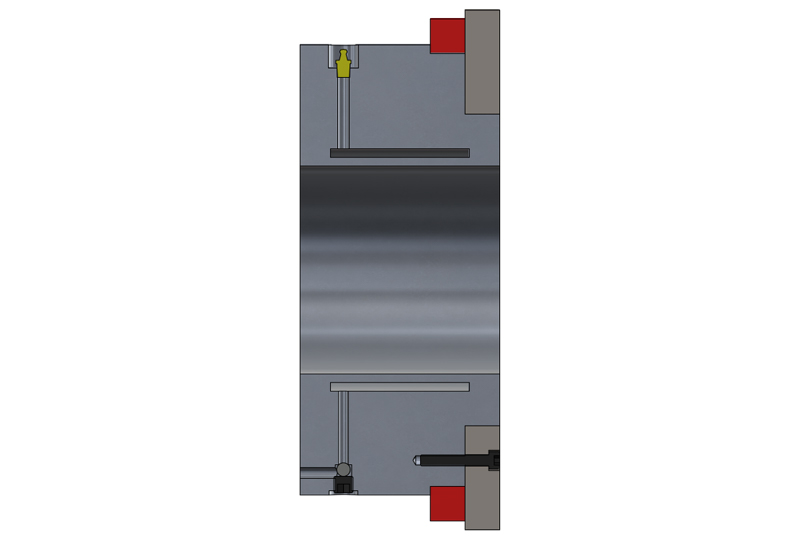

Learn moreClamp Rings

Model 902

Circular knife and stripper ring with steel core are mounted on the same seat and bolted against the shoulder. The hydraulic chamber extends under the knife seat.

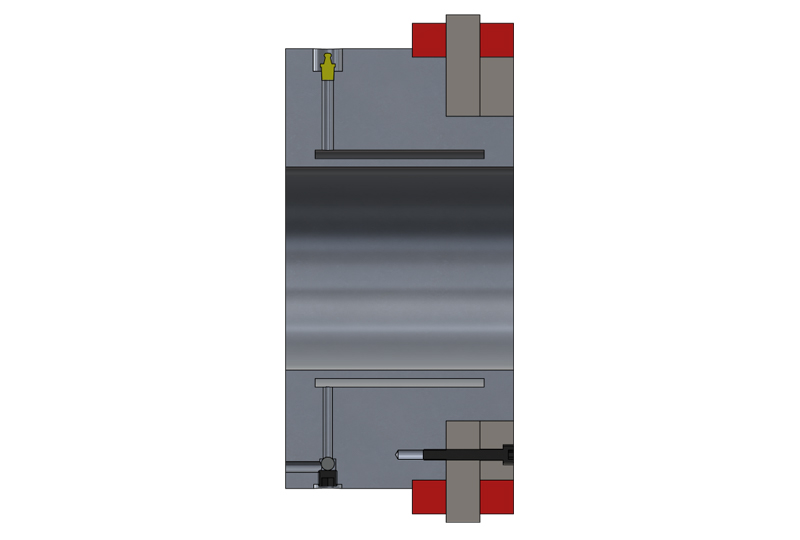

Learn moreClamp Rings

Model 903

Circular knife I.D. equals the clamp ring I.D. The knife is bolted against the face of the clamp ring.

Learn moreClamp Rings

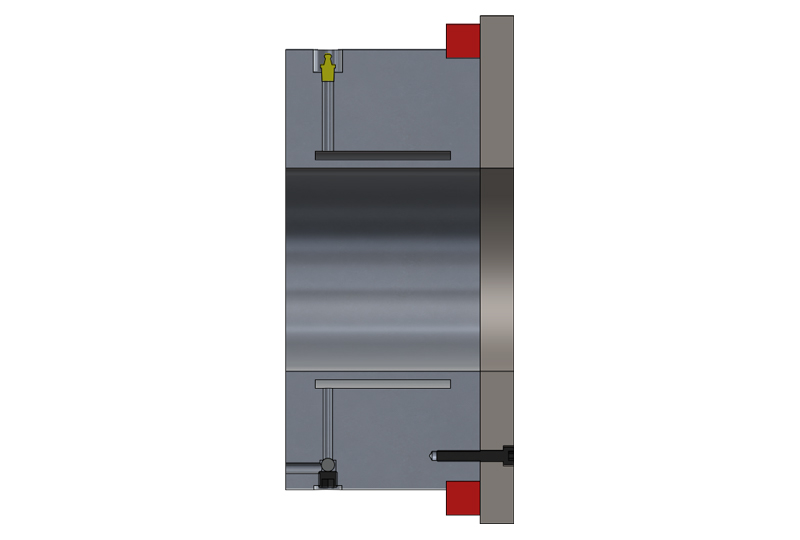

Model 921

Circular knife is mounted on the seat and bolted against the shoulder. The hydraulic chamber extends under the knife seat.

Learn moreClamp Rings

Model 922

Circular knife and stripper ring with steel core are mounted on the same seat and bolted against the shoulder. The hydraulic chamber extends under the knife seat.

Learn moreClamp Rings

Model 923

Circular knife I.D. equals the clamp ring I.D. The knife is bolted against the face of the clamp ring.

Learn moreClamp Rings

Model 931

An inboard stripper ring and circular knife are mounted on separate seats with the knife bolted to the shoulder. The hydraulic chamber extends under the knife seat.

Learn moreClamp Rings

Model 932

Circular knife and stripper ring with steel core are mounted on the same seat and bolted against the shoulder to retain an inboard, coreless stripper ring on a separate seat. The hydraulic chamber extends under the knife seat.

Learn moreClamp Rings

Model 933

Circular knife I.D. equals the clamp ring I.D. The knife is bolted against the face of the clamp ring. Retains inboard, coreless stripper ring

Learn moreClamp Rings

Model 941

An inboard stripper ring and circular knife are mounted on separate seats with the knife bolted to the shoulder. The hydraulic chamber extends under the knife seat.

Learn moreClamp Rings

Model 942

Circular knife and stripper ring with steel core are mounted on the same seat and bolted against the shoulder to retain an inboard, coreless stripper ring on a separate seat. The hydraulic chamber extends under the knife seat.

Learn moreClamp Rings

Model 943

Circular knife I.D. equals the clamp ring I.D. The knife is bolted against the face of the clamp ring. Retains inboard, coreless stripper ring.

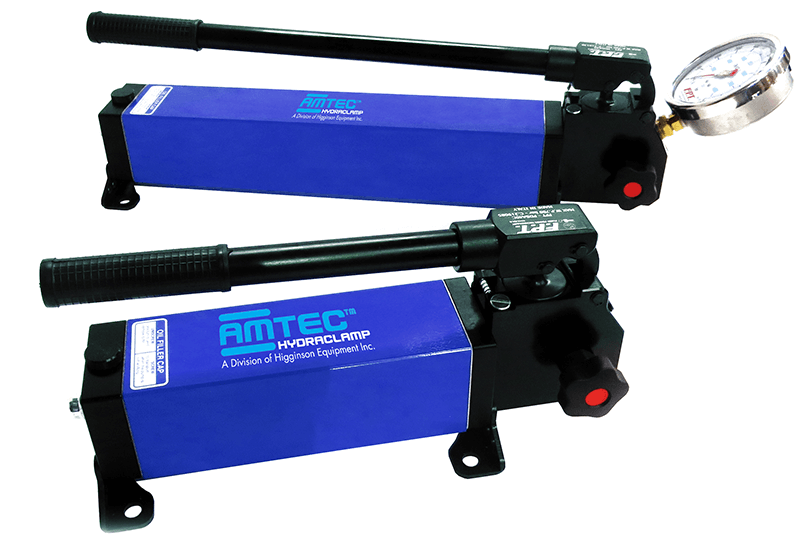

Learn moreHandpumps

CHAIN Series 112.100.200

A portable, grease cartridge type handpump with chain-type retraction handle for pressurizing all Amtec Hydraclamp F-Type clamping devices up to 700 bar (10,150 psi) maximum.

Learn moreHandpumps

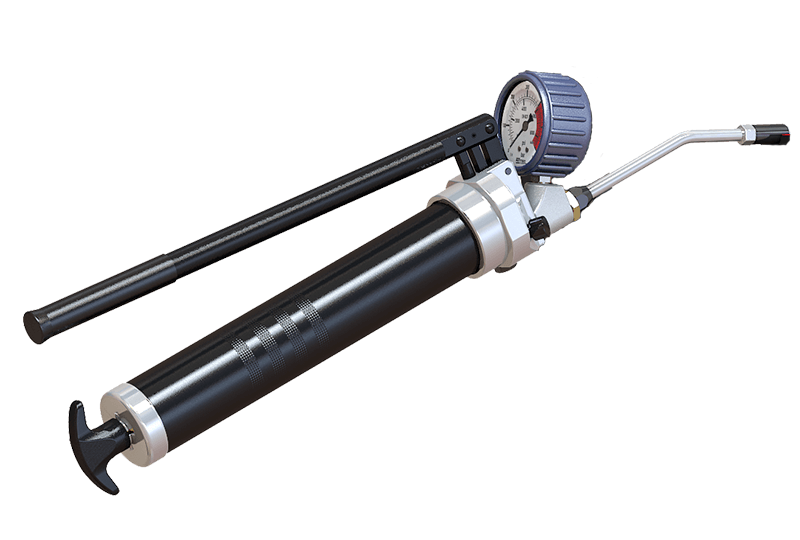

ROD Series 112.110.210

A portable, grease cartridge type handpump with rod-type retraction handle for pressurizing all Amtec Hydraclamp F-Type clamping devices up to 700 bar (10,150 psi) maximum.

Learn moreHandpumps

Oil Handpumps Series 114.427

We custom engineer Amtec Series 114.427 oil handpumps to handle high pressure requirements for many types of oil activated clamping devices. Decades of field engineering have resulted in a safe, convenient and durable handpump to meet most specifications.

Learn moreMobile and Bulk-Fill Pumps

Mobile Grease Pumping System Series 125.200

A permanently mounted, portable, air-powered pump for pressurizing all Amtec grease activated clamping devices up to 517 bar (7500 PSI).

Learn moreMobile and Bulk-Fill Pumps

Bulk Fill Pumping System Model 193.112.110.011

The Amtec Hydraclamp bulk fill system takes the pain and mess away from using individual grease cartridges. When combined with our 112.110.210 Series Rod Type Handpump, the system provides months worth of grease supply while never having to open up the handpump.

Learn moreAccessories

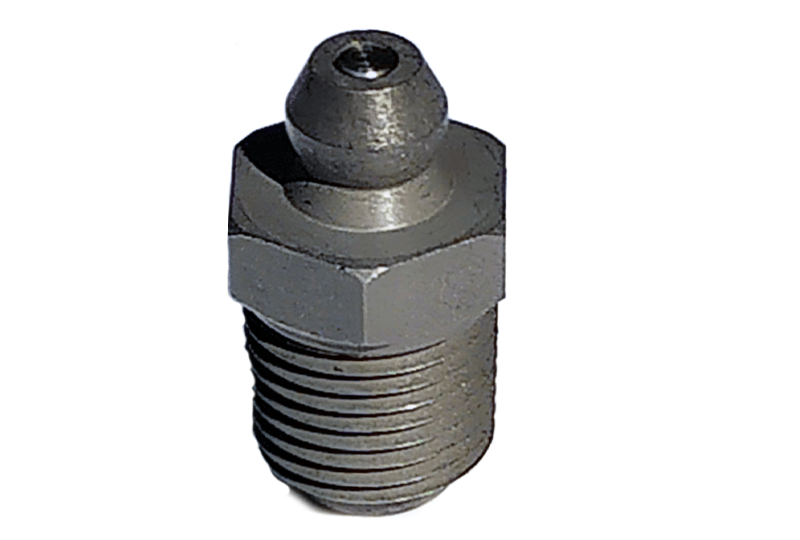

F-Nipple

Part # 710.101.005

Specially engineered one-way valve, high-pressure, heavy-duty, grease transfer fitting for use in all Amtec F-Type Hydraulic Nuts and other special lubrication applications.

Learn moreAccessories

F-Coupler

Part # 641.101.103

Special Four-Jaw Coupler; heavy-duty, high-pressure version, for reliable, efficient grease transfer from the Amtec Handpumps to the Amtec F-Nipple mounted in the Amtec F-Type Hydraulic Nuts.

Learn moreAccessories

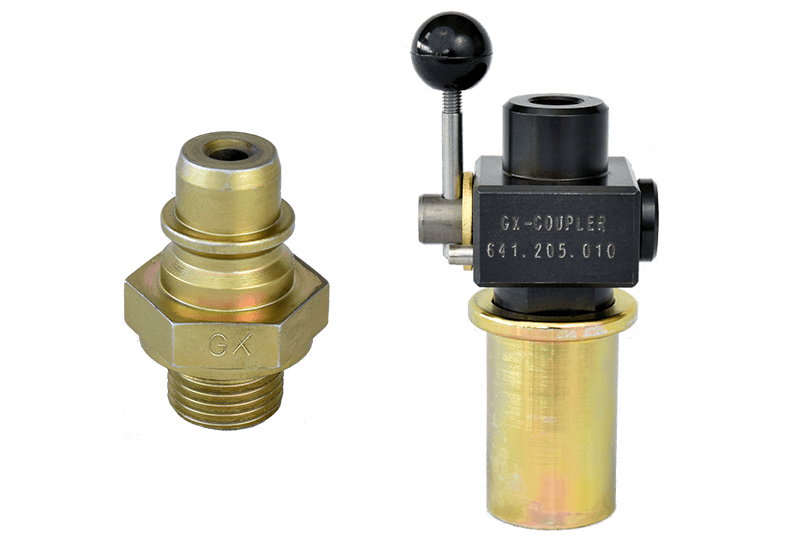

GX Coupler and GX Nipples

Models 641.205.010 / 710.205.010 700 BAR Working Pressure

This unique, compact, Amtec designed and built, highpressure oil connector and nipple arrangement allows for rapid connection and release with full pressure maintained in the associated clamping device.

Learn moreAccessories

GR Coupler and GR Nipples

Models 641.204.010 / 710.204.010 700 BAR Working Pressure

The Amtec Hydraclamp GR-Nipple comes with all double-acting oil-activated clamping systems. The nickel plating differentiates it from the zinc coloured GX-Nipple, and the GR-Nipple is used only for the low-pressure retraction of double-acting clamps.

Learn moreAccessories

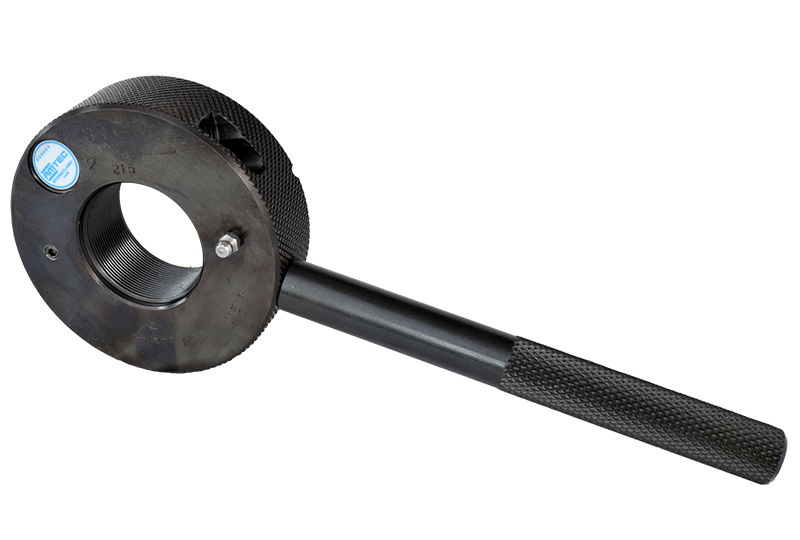

Assist Bars

For Retracting Thrust Rings

Use assist bars to retract the thrust ring into the nut body after production and before removing the clamp. The assist bar also helps remove nuts on sticky arbors while preventing hammering or other costly damage to clamps.

Learn moreAccessories

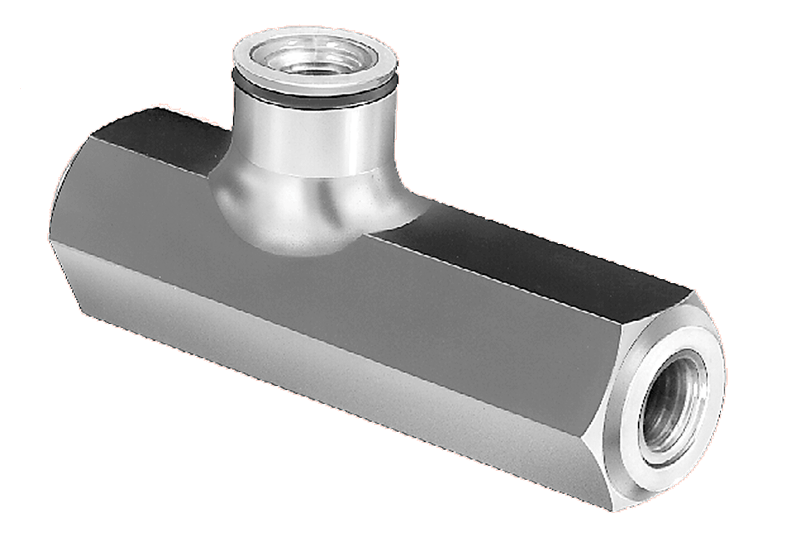

RH1 Pilot Operated Check Valve

Used with H-450 oil activated hydraulic nuts rated for over 10,000 PSI, this check valve locks hydraulic pressure into our H-Type nuts to provide an extended period of leak-free production.

Learn moreAccessories

High-Pressure Hose Assemblies

Used with all oil-activated Amtec Nuts, including H-Type and GX-Type.

Learn moreAccessories

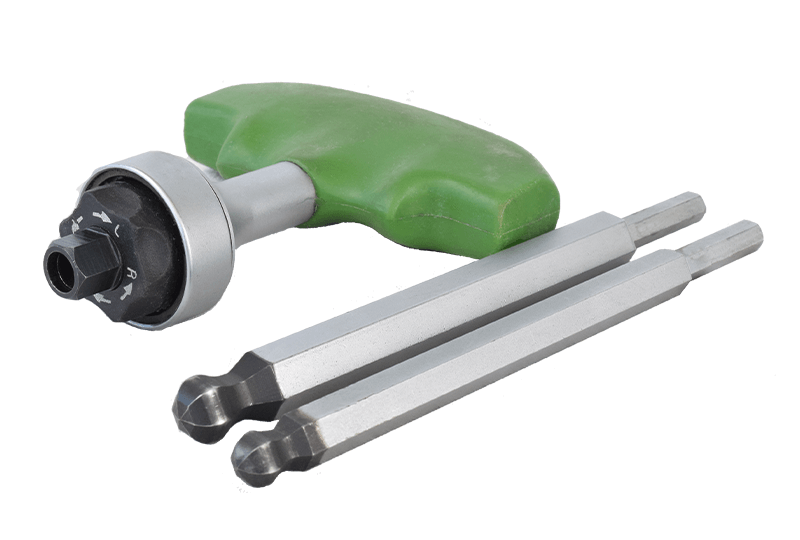

Hex Wrenches

381.102.000.010 for K-Nuts

Ratcheting hex wrench set for quick operation of the various hex screws used in Amtec Hydraclamp Hydraulic Nuts.

Learn moreAccessories

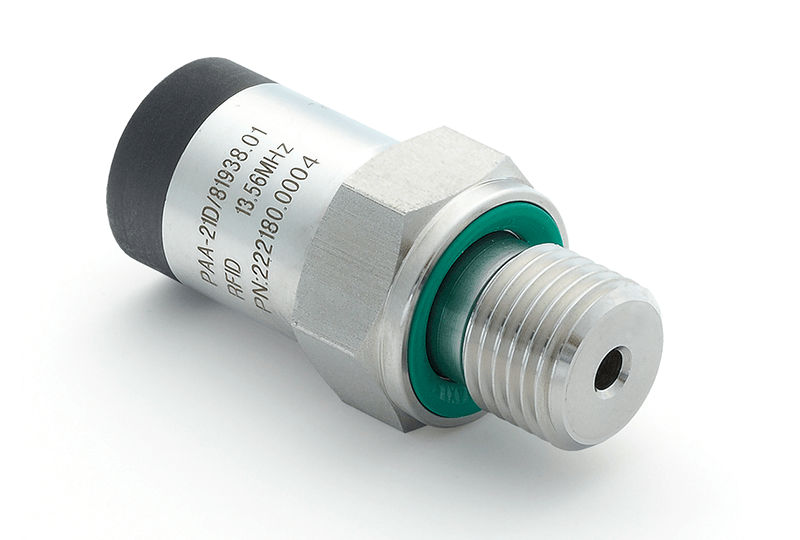

Series 550 Pressure Transponder

with PASSIVE RFID Transponder Interface for use with AMTEC HYDRAULIC NUTS

This series is a unique combination of an extremely sturdy, tried-and-tested industrial pressure transmitter and RFID (radio frequency identification) wireless technology used to accurately measure the setup pressure of Amtec Hydraclamp Hydraulic Clamping Devices.

Learn moreSorry, your search did not return any results.